- Pre-Engineered Metal Building Systems

- TRACDEK® Roofing & Cladding Systems

- Interarch Life - Non Industrial Buildings

- TRAC® Suspended Ceiling Systems

- Pre-Engineered Heavy Steel Structures for Tall Buildings and Infrastructure Applications

Interarch delivered Maintenance Depot project for Mumbai Metro in Maharashtra

Interarch delivered Maintenance Depot project for Mumbai Metro in Maharashtra Interarch delivered a Pre-Engineered Building for Jay Agro Industries in Gujarat

Interarch delivered a Pre-Engineered Building for Jay Agro Industries in Gujarat Interarch delivered Pre-Engineered Building for SMS India Pvt Ltd in Odisha

Interarch delivered Pre-Engineered Building for SMS India Pvt Ltd in Odisha Interarch delivered Project for Hindustan Unilever Ltd in Pondicherry

Interarch delivered Project for Hindustan Unilever Ltd in Pondicherry  Interarch delivered Light Steel Building for NTPC Ltd in Karnataka

Interarch delivered Light Steel Building for NTPC Ltd in Karnataka Interarch delivered Project for Tata Motors Ltd in Karnataka

Interarch delivered Project for Tata Motors Ltd in Karnataka Interarch delivered Manufacturing Unit for Nitin Lifesciences Ltd in Himachal Pradesh

Interarch delivered Manufacturing Unit for Nitin Lifesciences Ltd in Himachal Pradesh  Interarch delivered a Process Plant for Sunita Hydrocolloids Pvt Ltd in Rajasthan

Interarch delivered a Process Plant for Sunita Hydrocolloids Pvt Ltd in Rajasthan Interarch delivered a Manufacturing Unit for ABB India Ltd in Gujarat

Interarch delivered a Manufacturing Unit for ABB India Ltd in Gujarat Interarch delivered Rice Mill Project for REI Agro Ltd in Haryana

Interarch delivered Rice Mill Project for REI Agro Ltd in Haryana Interarch delivered Stadium Project for UPRNN in Uttar Pradesh

Interarch delivered Stadium Project for UPRNN in Uttar Pradesh Interarch delivered Warehouse Project for M.K international in Tamil nadu

Interarch delivered Warehouse Project for M.K international in Tamil nadu Interarch delivered an Indoor Stadium Cum Auditorium for Indian Heritage School in Punjab

Interarch delivered an Indoor Stadium Cum Auditorium for Indian Heritage School in Punjab Interarch delivered Manufacturing Unit for Sansera Engineering Pvt Ltd in Karnataka

Interarch delivered Manufacturing Unit for Sansera Engineering Pvt Ltd in Karnataka Interarch delivered Manufacturing Unit for Skoda Auto India Pvt Ltd in Maharashtra

Interarch delivered Manufacturing Unit for Skoda Auto India Pvt Ltd in Maharashtra Tristar Infrastructure Pvt. Ltd

Tristar Infrastructure Pvt. Ltd Toyota Kirloskar Ltd, Bangalore, Karnataka

Toyota Kirloskar Ltd, Bangalore, Karnataka Interarch delivered a G+2 Corporate Office Building for Reliance Industries Ltd in Maharashtra

Interarch delivered a G+2 Corporate Office Building for Reliance Industries Ltd in Maharashtra Hotel Building, Goa

Hotel Building, Goa Interarch delivered Manufacturing Unit for General Motors India Pvt Ltd in Gujarat

Interarch delivered Manufacturing Unit for General Motors India Pvt Ltd in Gujarat  Interarch delivered Manufacturing Unit for Ford India Pvt Ltd in Gujarat

Interarch delivered Manufacturing Unit for Ford India Pvt Ltd in Gujarat HNG Float Glass

HNG Float Glass Jain Irrigation System

Jain Irrigation System Interarch delivered a Manufacturing Unit for SKF Technologies (India) Pvt Ltd in Gujarat

Interarch delivered a Manufacturing Unit for SKF Technologies (India) Pvt Ltd in Gujarat Interarch delivered Warehouse Project for Western Refrigeration Pvt Ltd in Gujarat

Interarch delivered Warehouse Project for Western Refrigeration Pvt Ltd in Gujarat Interarch delivered Modern Logistic Park for Safexpress Pvt Ltd in Haryana

Interarch delivered Modern Logistic Park for Safexpress Pvt Ltd in Haryana  Interarch delivered a Manufacturing Unit for Mahindra Aerospace Pvt Ltd in Karnataka

Interarch delivered a Manufacturing Unit for Mahindra Aerospace Pvt Ltd in Karnataka Interarch delivered a Retail Outlet for METRO Cash and Carry India Pvt Ltd in Punjab

Interarch delivered a Retail Outlet for METRO Cash and Carry India Pvt Ltd in Punjab Interarch delivered Modern Logistic Park for IndoSpace in Haryana

Interarch delivered Modern Logistic Park for IndoSpace in Haryana Interarch delivered Pre-Engineered Building for Jash Engineering Ltd in Madhya Pradesh

Interarch delivered Pre-Engineered Building for Jash Engineering Ltd in Madhya Pradesh Interarch delivered Pre-Engineered Manufacturing Unit for Fiat India Automobiles Pvt Ltd in Maharashtra

Interarch delivered Pre-Engineered Manufacturing Unit for Fiat India Automobiles Pvt Ltd in Maharashtra

The Paint Industry has been growing at a healthy rate over the past few years; Asian Paints is the market leader in decorative paints both distemper as well as emulsion paints. The company has a market share of over 65% of the decorative paints in India.

The main challenge in front of Interarch at this time was to finish the project in the stipulated time period along with high safety expectations of the client. Another challenge in front of Interarch was the extreme dimensions of the buildings required by client for manufacturing process and stacking of raw materials, the entire project has 18 buildings in totality had variable heights with buildings towering at those of up to 30 M and had clear spans of up to of 44 M. The total project consumed more than 3000 MT of steel for structural system and around 70,000 Sq. of roofing & sheeting was supplied and installed.

The main challenge in front of Interarch at this time was to finish the project in the stipulated time period along with high safety expectations of the client. Another challenge in front of Interarch was the extreme dimensions of the buildings required by client for manufacturing process and stacking of raw materials, the entire project has 18 buildings in totality had variable heights with buildings towering at those of up to 30 M and had clear spans of up to of 44 M. The total project consumed more than 3000 MT of steel for structural system and around 70,000 Sq. of roofing & sheeting was supplied and installed.

The entire pre-engineered steel was manufactured in Interarch Pantnagar plant and to overcome the shortness of time 3 shifts with over 150 workers & supervisor’s was started for nearly 2 months. Separate bays were created in the manufacturing plant to paint the rafters and beams as desired by the client. It took over 2 months to manufacture the steel and roofing system required.

Further, to save time no scaffolding were used and only electronic boom lifts were employed with specially trained manpower. For the first time safe roof access of 35 M high was created by Interarch of Pipe Structure and for safety inspection.

Further, to save time no scaffolding were used and only electronic boom lifts were employed with specially trained manpower. For the first time safe roof access of 35 M high was created by Interarch of Pipe Structure and for safety inspection.

The client has also awarded Interarch Building Products for ensuring safe & healthy work environment at site. The client has also awarded Interarch Building Products for ensuring safe & healthy work environment at site.

| Project Name | Asian Paints Ltd |

|---|---|

| Building Location | Village Khandala, Pune Satara Road, Maharashtra |

| Building Usage | Greenfield expansion projects for Asian Paints |

| Tonnage of building | 3,000 MT |

| Roofing Supplied in MT | 70,000 Sq. M |

| Value of Project | 40 Cr. |

| Area of Project | 65000 Sq. M |

| Important Feature of Project |

|

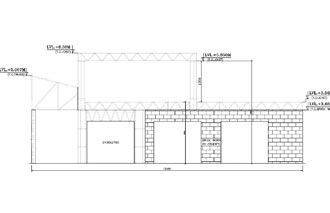

Nitin Lifesciences Ltd. a closely held limited company setup in 2005 has a world class facility to manufacture SVPs, Eye/Ear Drops, Dry Powder Injectables and Veterinary Injectable Products. Both the facilities of Nitin Lifesciences Ltd. are WHO- GMP certified. The organization is a renowned contract manufacturing for various leading pharmaceutical companies for the domestic & export markets.

Interarch delivered a G+2 floor building in Ponta Sahib, Himachal Pradesh for Nitin Lifesciences. The building is 140 meters in length & 40 meters in width with a total height of 11 meters for one building. The complete project will be delivered in phases the 1st phase with the construction of one building has been completed.

Interarch delivered a G+2 floor building in Ponta Sahib, Himachal Pradesh for Nitin Lifesciences. The building is 140 meters in length & 40 meters in width with a total height of 11 meters for one building. The complete project will be delivered in phases the 1st phase with the construction of one building has been completed.

The building completed has been provided with a round cut in the roofing to provide space for the boiler. Especially on client request a square shaped multi – level Pipe Rack is being provided which will connect both buildings. 1 level of Mezzanine is being provided in the Utility Block as well.

The project was completed in a mere time of 3.5 months. With a total manpower of 75 people of which 3 were supervisors and 1 engineer was specifically assigned to the project.

| Building Location | Ponta Sahib, Himachal Pradesh |

|---|---|

| No. Of Buildings | 2 |

| Building Usage | Drug Formulation Unit & Utility Block |

| Tonnage of building (Main Building) | 605 Tonnes |

| Building Area (Main Building) | 11000 Sq. M |

| Length (Main Building) | 140 M |

| Width (Main Building) | 40 M |

| Height (Main Building) | 11 M |

| Features (Main Building) |

|

Hi Rib® Roofing – Azure Blue

Hi Rib® Roofing – Azure Blue Wall Cladding System – Azure Blue

Wall Cladding System – Azure Blue

Interarch is engineering, manufacturing and delivering the first Guar Gum Buildings Project in India, till now no project has been done in Pre-Engineered technology. Till date all construction in this process industry take in RCC only due to complicity of the buildings but for the first time after complex engineering and innovative design Interarch has been awarded the project of new manufacturing plant of Sunita hydrocolloids at Jodhpur, Rajasthan

This building will be utilized as a process plant for making Guar Gum powder. There are 6 different units or tower in this project. Each tower has a 3 level Mezzanine floor with deck panel with floor opening for equipment pipeline.

Total height of each tower is 15.3 M. The most important aspect of this project is that this project is that all the towers will be covered by a single shed of 33M clear span and a clear height of 23M.

Total height of each tower is 15.3 M. The most important aspect of this project is that this project is that all the towers will be covered by a single shed of 33M clear span and a clear height of 23M.

Interarch further connected all the towers internally by walkway thereby giving it a one point access. One can travel through all the towers & floors. Industrial louvers have also been installed for proper ventilation. Each wall has a Liner panel with insulation.

Each floor is designed for Static as well as Dynamic loading, that to without Cross Bracing and all Mezzanine with Bi-directional force transmission with Mezzanine beam.

This project is designed according to the latest IS design code (IS 800:2007) with consideration given to all the geographical data like wind velocity, seismic zone as per IS standard for particular site.

| Project Name | Sunita Hydrocolloids |

|---|---|

| Site Location | Jodhpur, Rajasthan |

| Building Usages | Process plant for the production of Guar Gum Powder. |

| Design Code | Latest IS design code IS 800:2007 |

| Project Area | 2400 Sq. M |

| Total Tonnage | 650 Ton |

| Special Features |

|

Interarch an expert in delivering highly complex buildings is developing a project for ABB Ltd. a leader in power and automation technologies that enable utility and industry customers to improve performance while lowering environmental impact.

Interarch an expert in delivering highly complex buildings is developing a project for ABB Ltd. a leader in power and automation technologies that enable utility and industry customers to improve performance while lowering environmental impact.

The project has 2 buildings of which one will be utilized as factory for manufacturing of Transformers unit (Pass factory) and the other for Dry Transformer. The project is located in Baroda (Savli), Gujarat.

Total area for the project will be 14000 Sq. M with a total building tonnage of more than 1200 MT. Both the buildings developed have varied dimensions and high complexity factor.

Interarch has followed very high standards of safety as per the requirement of ABB Ltd.

| Project Name | ABB Ltd. | ABB Ltd. |

|---|---|---|

| Building Usage | Transformer Manufacturing unit(Pass Factory) | Dry Transformer factory |

| Tonnage of building | 600 MT | 600 MT |

| Roofing Supplied | 99 tons | 131 tons |

| Project Area | 6500 Sq. M | 7500 Sq. M |

| Special Features |

|

|

Hi Rib® Wall Cladding – Off white color

Hi Rib® Wall Cladding – Off white color  SS- 2000® Roofing System – Bare Galvalume Color

SS- 2000® Roofing System – Bare Galvalume ColorREI Agro is the largest basmati rice processing and marketing company in the globe. From modest beginnings in 1996, the company has grown to hold the largest market share of the basmati rice segment worldwide. Today, REI Agro is an integrated player, undertaking activities right from procuring paddy to drying, de-husking, milling and polishing, color sorting, grading, inspection, packing, branding, distribution and retailing.

REI Bawal is state of art Rice milling plant which once complete will help the company to increase the production level.

| Building Location | Bawal, Haryana |

|---|---|

| Building Usage | Rice milling plant |

| Value | 6.7 CR |

| Building Area | 5600 Sq. M including Mezzanines |

| Length | Building 1: 60 M Building 2: 23 M |

| Width | Building 1: 48 M Building 2: 24 M |

| Height | Building 1: 29 M Building 2: 14 M |

| Feature |

|

| Project Name | TATA Motors Ltd |

|---|---|

| Building Location | Dharwad, Karnataka |

| Building Usage | Manufacturing Facility |

| No. of Buildings | 11 |

| Tonnage of building | 5400 MT |

| Roofing Supplied in MT | 83,000 Sq. M |

| Value of Project | 86 Cr. |

| Area of Project | 72,000 Sq. M |

| Manpower deployed | 500 |

| Important Feature of Project |

|

| Project Name | M/s Uttar Pradesh RajkiyaNirman Nigam Limited |

|---|---|

| Building Location | Safai, Etawah, UP. |

| Building Usage | Indoor Stadium |

| Length | 86.99 m O/O |

| Width | 73.18 m C/C |

| Height | 12 m clear |

| Roofing Supplied | 7640 Sq. M |

| Area of Project | 6366 Sq. M |

| Value of the Project | 5.4 Cr. |

| Important Feature of Project |

|

|

|

Interarch, India's leading Turnkey Pre- Engineered Metal Building & Steel Construction Company. Interarch successfully delivered warehousing project for M.K. International. The building is a storage unit of BATA Industries Ltd. for their footwear merchandise.

Interarch, India's leading Turnkey Pre- Engineered Metal Building & Steel Construction Company. Interarch successfully delivered warehousing project for M.K. International. The building is a storage unit of BATA Industries Ltd. for their footwear merchandise.

M.K. International is a well-known brand in the southern market for their fleet of warehouses. The particular project is located at a place where the storage units of many Companies are present Chennai.

The total area of the building is 5360 Sq. M. This project has a continuous canopy of 4 M width for a full length of 160 M. 2 identical warehouses of same dimensions have been constructed for M.K International both facing each other.

| Project Name | M.K. International |

|---|---|

| Building Usage | Warehouse rented to BATA |

| Total Area | 5360 Sq. M |

| Length | 160 M |

| Width | 33.53 M |

| Height | 10 M clear under-knee |

| Features |

|

Interarch has designed, Engineered and executed various projects for Educational Institutes. Indian Heritage

School is an example of Interarch's commitment, design, & engineering abilities.

Interarch has designed, Engineered and executed various projects for Educational Institutes. Indian Heritage

School is an example of Interarch's commitment, design, & engineering abilities.

Indian Heritage School is possibly one of the best equipped residential School of North India, both in design and facilities, with lot of emphasis on latest educational technologyto enable the students to realize their full potential. The School is affiliated to ICSE Board, New Delhi.

The application, Indoor Stadium cum Auditorium in Pre-Engineered

Metal Building was first in the Punjab region. Pre-Engineered Steel Buildings

can be used for various types of Institutional buildings as well.

The application, Indoor Stadium cum Auditorium in Pre-Engineered

Metal Building was first in the Punjab region. Pre-Engineered Steel Buildings

can be used for various types of Institutional buildings as well.

The building has column less clear span of 25 M with total area of 1333 Sq. M. The building will be utilized for games like Lawn Tennis, Basketball, seminars, events etc.

| Project Name | Indian Heritage School |

|---|---|

| Building Location | Pathankot, Punjab |

| Building Usage | Indoor Stadium Cum Auditorium |

| Width | 25 M |

| Length | 53.34 M |

| Height | 7.62 M |

| Area of Project | 1333 Sq. M |

| Features |

|

Interarch unmatched expertise in the Engineering Industry reflects through the projects delivered for all the big brands

in the Engineering Industry.

Interarch unmatched expertise in the Engineering Industry reflects through the projects delivered for all the big brands

in the Engineering Industry.

Sansera Engineering is one of the leading brands of engineering companies globally that builds its own CNC-SPMs, allowing its customers to benefit from a dual advantage - cost-effectiveness and enhanced machining capabilities.

Its vast machine pool and an expert engineering team with the highest level of technical and professional competence produce products that are complex and meet the high

quality standard of its customers.

Its vast machine pool and an expert engineering team with the highest level of technical and professional competence produce products that are complex and meet the high

quality standard of its customers.

The project covers a total area of 1680 Sq. M with a total Roofing & Cladding supplied for a 3829 Sq. M. The structure designed is supporting a 1 crane of 15 MT. The building delivered has a clear height of 14 M.

| Project Name | Sansera Engineering Pvt. Ltd. |

|---|---|

| Building Usage | Forging and Machine Unit |

| Dimensions | Length - 56 M, Width - 30M, Height - 14.337 M |

| Project Area | 1680 Sq. M |

| Tonnage | 68 MT |

| Roofing Supplied | 3829 Sq. M |

| Features |

|

Interarch, India's leading turnkey Pre-Engineered Metal Building & Steel Construction Company delivers automotive assembly unit for Skoda Auto India for Audi Manufacturing facility

Interarch, India's leading turnkey Pre-Engineered Metal Building & Steel Construction Company delivers automotive assembly unit for Skoda Auto India for Audi Manufacturing facility

SKODA has been operating in India since November 2001 as a subsidiary of SKODA Auto from Czech Republic (Volkswagen Group). It is one of the fastest growing car manufacturers in Europe. It has set up a state-of-the-art manufacturing facility in MIDC Shendra near Aurangabad, Maharashtra. The facility is spread across 300,000 Sq. M. it has a network of 106 outlets across the country.

it has a network of 106 outlets across the country.

The project delivered has a main building & other sub-structures and lean to buildings attached to it. A footbridge is constructed connecting existing plant and the new building.

| Project Name | Skoda Auto India |

|---|---|

| Project Location | Aurangabad, Maharashtra |

| Building Usage | Assembly Unit of AUDI |

| Tonnage | 1400 MT |

| Area of the Main Building | 19375 Sq. M |

| Length | 193.75 M c/c |

| Width | 100.00 M c/c |

| Sheeting Supplied | 27600 Sq. M |

| Special Features |

|

Interarch has successfully designed, engineered and delivered the Warehousing facility for Tri-Star Infrastructure Pvt. Ltd.

Interarch has successfully designed, engineered and delivered the Warehousing facility for Tri-Star Infrastructure Pvt. Ltd.

Tristar is one of the largest service providers and rapidly growing Infrastructure Company, having more than 200 people on roll and offices in most of the major cities within the country and Dubai. Seeing the current growth and revamping of total Indian Infrastructure Market which includes railways, airports, roads, bridges and hydro powers, Tristar envisaged a good opportunity and has created joint ventures with various International organizations.

Interarch has always been a leader when it comes to following the safety standards. Tri-star has awarded Interarch with "Certificate of Appreciation" for Zero Accidents.

A highly complex building with an area of over 80,000 Sq. M has been executed by Interarch.

| Project Name | Tri-Star Infrastructure Pvt. Ltd. |

|---|---|

| Project Location | Pipavav, Gujarat |

| Building Usage | Fertilizer Warehouse at Sea Coast |

| Steel Tonnage of the project | 2000 MT |

| Roofing & Cladding Supplied | 82,000 Sq. M |

| Total Area of Project | 80,000 Sq. M |

| Special Features |

|

|

|

Interarch unmatched expertise in the automotive sector reflects through the projects we have delivered for all the big brands in the automotive industry.

Interarch unmatched expertise in the automotive sector reflects through the projects we have delivered for all the big brands in the automotive industry.

Toyota Kirloskar Motor Private Limited is joint venture between Toyota Motor Corporation and the Kirloskar Group, for the manufacture and sales of Toyota cars in India. It currently is the 5th largest car maker in India after Maruti Suzuki, Hyundai, Tata, and Mahindra.

The company Toyota Kirloskar Motor Private Limited (TKMPL) according to its mission statement aims to play a major role in the development of the automotive industry and the creation of employment opportunities, not only through its dealer network, but also through ancillary industries with a business philosophy of "Putting Customer First".

The project executed for the Toyota Kirloskar was one of the complex projects delivered with panache by Interarch. Total tonnage of the building is 2800 MT and a total area of 5800 Sq. M.

| Project Name | Bangalore |

|---|---|

| Project Location | Bangalore |

| Building Usage | Paint Shop |

| Building Area | 5800 Sq. M | Width | Area - (01 , 02 ,03 ) – 12.0 m Area - (04 , 05 ,06 ) – 15.0 m Area – (07) - 9.0 m |

| Special Features |

|

|

|

Interarch engineered, manufactured & delivered the first Pre- Engineered Steel Multi storey officecomplex in India for Reliance Industries Ltd.

Reliance office space is a G+2 multi-level building built for headquarter of the Reliance MukeshAmbaniGroup. It covers 50,000 sq. meters of office space and accommodates 5 star office facilities inside acompletely steel structure cladded with structural glazing and aluminum composite panels.

| Building Usage | Multi-Storey G+ 2Office Building |

| Tonnage of Buildings | 5,000 MT |

| Covered Area | 50,000 Sq. M |

| Project Highlights |

|

|

|

Interarch successfully delivered first full PEB auto plant in India, The Halol project for General Motors. This plant was first of its kind in the country, a benchmark for Pre-engineered buildings in automotive sector. Total area of the project was 10,385 sq. m the project was completed in 4 months. The Project was carried out as per General Motors India safety systems and procedures and very high standards of quality were followed as per the Quality Assurance Plan and other technical specifications relevant to International Standards.

| Project Name | General Motors India |

|---|---|

| Building Area | 10385 Sq. M |

| Material Supplied | 235 MT |

| No. of Buildings | 4 |

| Features |

|

Interarch Light Building systems are a well suited system for applications like Hotels, Residential, Farmhouses, Institutional and commercial buildings. Interarch Light Buildings system has got un-matched advantages over the conventional construction system like Water Proof, and moisture proof building, Longer life span and easy to maintain, Dismantling possibilities if required and many more. Interarch has designed, engineered and delivered a hotel in light building system for one of its Client in Goa.

It took a mere of1 month by Interarch to deliver the project. The project covers an area of 139 Sq. M. total tonnage of the building is 4MT and has a Mezzanine floor. The external finish is Cement Board.

| Project Name | Krishna Decorators |

|---|---|

| Building Usage | Hotel Building |

| Project Location | Goa |

| Area Of Project | 139 Sq. M | Roofing Supplied | Composite Deck Sheet | Features | Flat Roof |

| Internal & External Finish Type , Material & Color | Internal Finish - Cement Board + Gypsum Board for Reception area External Finish - Cement Board + Galvalume Steel |

|

|