- Pre-Engineered Metal Building Systems

- TRACDEK® Roofing & Cladding Systems

- Interarch Life - Non Industrial Buildings

- TRAC® Suspended Ceiling Systems

- Pre-Engineered Heavy Steel Structures for Tall Buildings and Infrastructure Applications

TRACDEK® profiles are available in both ribbed and flat panels to give a variety of finishes for attractive roofing and cladding of domestic, commercial and industrial applications. The profiles are available in the following standard finishes:

All the roof and wall coverings are supplied with custom accessories such as flashing, cappings, futters, trims, fasteners, etc. which are formed out of the same substrates and coatings as the roof and wall covering panels.

TRACDEK® profiles are now available in Galvalume® Plus. A significant advance in protective coating for sheet steel roofing and cladding TRACDEK® Galvalume® Plus is a zinc-aluminum coated steel offering high corrosion resistance with a clear resin coating.

The alloy coating comprises of 55% aluminum, 43% zinc and 1.5% silicon. This coating combines the superior barrier protection of aluminum and the sacrificial cut edge protection of zinc.

TRACDEK® Galvalume® Plus is available in coating class AZ 150 (150 gm/m2 minimum coating mass) and offers 2-4 times the service life of traditional galvanized steel in similar coating thickness under severe environment conditions.

TRACDEK® Galvalume® profiles are supplied with an optional organic colour coating in silicon modified polyester or fluoropolymer (70% Kynar 500).

These colour coated profiles exhibit excellent life to first maintenance in excess of 20 years. Galvalume® is a registered trade mark of BIEC International, USA.

TRACDEK® is available in the following base materials in standard execution:

TRACDEK® Hi-Rib®, a pierced fixed roof and wall covering system, consists of structurally-engineered profiled panels that are available in single length (up to 12 metres) and are fixed by means of self-drilling fasteners. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing.

he patented fluted side lap makes TRACDEK®Hi-Rib® completely watertight.

The side lap is totally weatherproof. Any moisture drawn in by capillary action is trapped and dispersed by normal run-off.

Long lengths and weatherproof side lap allow TRACDEK®Hi-Rib® to be used safely on roof pitches as low as 3 degree (approximately 1 in 20) in single-sheet lengths, 5 degree (approximately 1 in 11) with end laps, and for vertical cladding.

| Total Coated Thickness (mm) | Approx. mass per unit area kg/ m2 | Approx. covrage per unit area m2/ ton | |

|---|---|---|---|

| Bare Gavalume® high tensile steel | 0.50 | 4.12 | 242 |

| Gavalume® high tensile steel, colour coate | 0.50 | 4.24 | 235 |

| Galvanised steel, colour coated | 0.50 | 4.25 | 235 |

| Galvanised steel, colour coated | 0.50 | 4.56 | 219 |

| Galvanised steel, colour coated | 0.55 | 5.03 | 198 |

| Galvanised steel, colour coated | 0.65 | 5.97 | 167 |

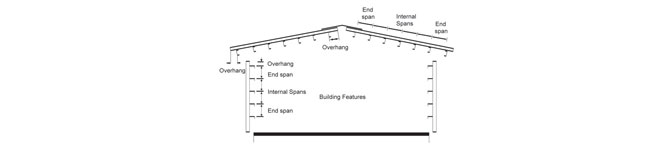

| Type of Span | 0.50 mm TCT steel (550 Mpa) | 0.50 mm TCT steel (240 Mpa) |

|---|---|---|

| Roofs | ||

| Single | 900 mm | 800 mm |

| internal span | 18000 mm | 1400 mm |

| End span | 1200 mm | 1000 mm |

| Overhangs | ||

| Without edges stiffening | 150 mm | 150 mm |

| With edges stiffening |

300 mm | 300 mm |

| Walls | ||

| Single span | 1500 mm | 1100 mm |

| internal span | 2000 mm | 1400 mm |

| End span | 1800 mm | 1200 mm |

| Overhangs | 300 mm | 300 mm |

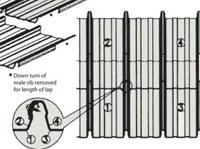

Sheets are lifted onto roof supports with ribs up and with overlapping ribs (female) facing towards the starting edge. To commence fixing, the first sheet is placed in position with the female rib, in line with other building elements, and fastened as recommended. The female rib (with turned-down free edge) of the second sheet is lapped over the male rib (with turned-out bottom edge) of the first sheet and the recommended side lap fasteners are inserted to hold the lap firmly in place before fastening the second sheet to supports. The second sheet procedure is followed for all subsequent sheets.

For walling applications, the procedure outlined for roofing is followed. The recommended minimum end lap for vertical wall cladding is 100 mm. When the roof pitch is less than 15 degree, or where the roof is exposed to extreme weather conditions, the tray between the ribs is turned up approximately 80 degree at the high end of the roof sheeting and turned down slightly at the low end. A Turn-up tool is available for this operation which can be carried out before or after sheets are fixed in position. If turned up after fixing, at least 25 mm clearance is required at the end of the sheet to position the tool.

Minimum end lap is 150 mm, and for roof pitches below 7 degree, the lap is sealed with a recommended sealant. The maximum roof run from top to bottom does not exceed 27,500 mm for a single run of sheeting. Expansion joints are required in sheeting for longer roof runs.

TRACDEK® Hi-Rib® roofing is fastened by conventional crest fixing to timber and steel supports; in each case there should be four fixings per sheet at all supports. Wall claddings are fixed by crest or valley fixing.

It is important for all fasteners located in pan to be as close as possible to ribs as shown.

Lap fasteners are essential to hold the side laps of sheets firmly in place and maintain a weather-proof joint. Side lap fasteners are required at midspans for purlin spacing over 900 mm and also for girt spacing over 1200 mm. In the applications where valley fixing is used, a side lap fastener is also required alongside each valley fastener, or a crest fastener is used at the side lap.

TRACDEK® Hi-Rib® should be fixed with the following hexagonal washer head with seal fasteners which are available from Interarch in corrosion protected zinc coated finishes with colour heads or in stainless steel.

Fixing through Crest to Hardwood Support: Type 17 No. 12-11 x 65 mm (self drilling)

Fixing through Pans to Handwood Supports (For walls only): Type 17 No. 10-12 x 25 mm (self drilling)

Crimp Curved TRACDEK® Hi-Rib® is developed to provide versatility and creativity. It brings new and refreshing design to commercial, industrial and domestic buildings.

The combination of curves and contours in concave and convex shapes with flats and angles in TRACDEK® Hi-Rib® produce many aesthetically pleasing buildings.

This design freedom can result in significant cost saving in construction mainly due to:

Crimp Curved TRACDEK® Hi-Rib® is available in polyester coated galvanized steel or organic coated Galvalume®.

For Crimp Curved TRACDEK® Hi-Rib®, the minimum radius of curvature for either concave or convex curving is 550 mm to inside of sheet.

Minimum length of sheet at either end of a curve is 180 mm at leading end and 200 mm at the lagging end

The sheets can be curved to 3 quarters of a full circle (for convex and concave) but to facilitate side lappings, semi circle maximum is recommended.

Maximum length of straight sheet that can be curved at its height (for Ridge Application) is approximately 12 metres.

TRACDEK® Hi-Rib® roof and wall systems are ideally suited for regions which receive heavy rainfall and can be used on slopes as low as 1 in 20.

TRACDEK® Hi-Rib panels can be used as internal liners for double-skin roof and wall construction, with or without insulation. TRACDEK® Hi-Rib curved panels are also offered for special architectural requirements.

TRACDEK® Klippon® is a concealed fixed snap-on seam roof/wall covering system that consists of structurally strong high-ribbed panels with wide-fluted pans for

efficient water shedding and are fixed by means of concealed clips. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or

wall framing. These are ideally suited for regions which receive heavy rainfall and

can be used on slopes as low as 1 in 20.

The clip-on side lap makes the Klippon® profile completely water-tight. The side lap

is totally weatherproof. Any moisture drawn in by capillary action is trapped and

dispersed by normal run-off.

Long lengths and weatherproof side lap allow the Klippon® profile to be used safely on roof pitches as low as 2 degree (approximately 1 in 30) for single length sheets, 3 degree (approximately 1 in 20) with end laps.

| Total Coated Thickness | Approx. mass per unit area (mm) | Approx. covrage per unit area m2/ ton Kg/m2 | |

|---|---|---|---|

| Bare Gavalume® steel | 0.55 | 5.87 | 170 |

| Gavalume® steel, colour coated | 0.58 | 6.02 | 166 |

| Gavalume® steel, colour coated | 0.68 | 7.15 | 140 |

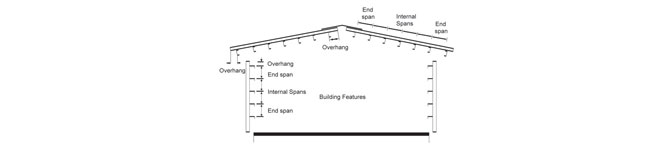

| Type of Span | 0.50 mm TCT steel (550 Mpa) | 0.50 mm TCT steel (240 Mpa) |

|---|---|---|

| Roofs | ||

| Single | 1500 | 2000 |

| End span | 1800 | 2300 |

| internal span | 2100 | 2700 |

| Overhangs + | 200 |

300 |

| Walls | ||

| Single span | 2300 | 2500 |

| End span | 2700 | 2900 |

| internal span | 2900 | 3000 |

| Overhangs + | 400 | 600 |

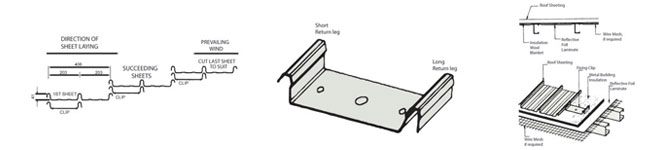

TRACDEK® Klippon® steel cladding is designed to be fastened to roof purlins or wall girts with fixing clips which are concealed during fixing and do not require any fastening holes through the steel sheets.

The clip for fastening Klippon® steel cladding requires only two fasteners per clip and provides an easy, positive engagement in the ribs of the profile.

The two fasteners are inserted only through the two punched holes.

Four dimples are also provided in the clip but these are for auxiliary fasteners only.

The clip has a short return leg and a long return leg. The clip must be positioned with the short leg engaging over the male rib of the under lapping sheet.

Because of the concealed clip fixing method, no fastening screws are visible and there is no screw penetration through the external sheeting.

Concealed fixing also offers an advantage of security. Entry into the premises by unscrewing of roof and wall cladding sheets is not possible. TRACDEK® Klippon® can be used for roofing large span factories, warehouses, commercial, educational, institutional, domestic and recreational buildings.

(Two fasteners are required per clip)

| Steel Support | ||

|---|---|---|

| Thickness | Directly to Support | Over Insulation Blanket |

| Upto 4.5 mm | No. 10-16 X 16 mm wafer-head | Increase to 32 mm long |

| self-drilling and tapping screw | screw, if required | |

| Exceeds 4.5 mm | No. 12-24 X 32 mm wafer-head | |

| self-drilling and tapping screw | ||

| Timber Support | ||

|---|---|---|

| Grade | Directly to Support | Over Insulation Blanket |

| Harwood | No. 10-12 X 25 mm wafer-head type 17 self-drilling and tapping screw |

Increase to 45 mm long screw, if required |

| Softwood | No. 10-12 X 45 mm wafer-head type 17 self-drilling and tapping screw |

No change |

On most jobs, single long length sheets can be ordered to reach from ridge to gutter, so that the end laps do not normally occur. This is possible because Klippon®

roofing and walling profiles are manufactured by a continuous process.

However, should it be necessary to use two or more shorter sheets to provide full length coverage, the locking ribs of Klippon® steel cladding are sufficiently flexible to enable it to be end lapped.

The illustration here depicts the correct method of placing the various profiles. The recommended minimum length of the end lap is 150 mm. The end lap should be weather-proofed by sealing it with non hardening silicon sealant. It can be further secured by using self tapping screws to the ribs.

TRACDEK® Klippon® can be used for roofing large span factories, warehouses, commercial, educational, institutional, domestic and recreational buildings.

TRACDEK® SS-2000®, also known as TRACDEK® Vertical Leg Structural Standing Seam Roof System, blends the aesthetics of an architectural panel with the strength

of a structural panel. These panels have good uplift ratings assuring the reliability of the roof and can go down to roof slopes of up to 1:50. The designer is thus afforded

a flexible tool to meet any design challenge.

TRACDEK® SS-2000® is a field seamed system that combines a slim rib with exceptional uplift resistance. This panel has been designed to withstand the most rigorous conditions. This systems features optional factory installed hot-melt mastic for low slope applications to ensure weather tight seams. Ribs are provided for added aesthetic value.

| Profile | SS 2000 |

| Snap Together | NO |

| Filed Seamed | YES |

| Min. Roof Slope | 1:50 |

| Transition | NO |

| Width Available | 430mm / 300mm |

| Delight Panels | YES |

| Solutions | YES |

| Clip Available | High or Low fixed High or Low floating |

| Seam Height | 51 mm |

A wide choice of concealed fastening clips is available for the system. These clips hold the panels firmly in place without exposed fasteners. Each clip system offers the ability to accommodate thermal movement.

The TRACDEK® SS-2000® system has been tested for uplift ratings to satisfy most building requirements.

Facility of on-site roll forming eliminates panel end lap condition. Panels are manufactured ‘at-the-eaves’ enabling single length panels on long roof runs.

The system is designed to be installed over open framing. 15 mm plywood, or a composite roof assembly may be used as alternate sub-structures.

Manufactured from high quality Galvalume® steel and by fully automated machines, TRACDEK® Wall profiles provide a reliable envelope for the steel building for the

years to come.

With its strengthened profiled troughs, the TRACDEK® Wall is a flat wall with

pleasant aesthetics which homogenizes with conventional brick walls.

Interarch pre-engineered buildings can be designed to accept most types of crane systems such as EOT, Monorail, Under-hung cranes and other load carrying devices like conveyors etc., in both clear-span and multi-span buildings. When a crane system is to be integrated, Interarch’s scope is limited to brackets and crane runway beams which support the crane system. Complete information on the crane system is required in order to design and estimate buildings with cranes.

Intermediate mezzanine floors are possible in metal buildings. Mezzanine floors can be provided in complete or partial area in pre-engineered buildings to suit loading requirements for office and storage. Mezzanine floors consist of steel decks, supported by joists framed to the mezzanine beams. Main mezzanine beams normally run across the width of the building and are located under the main rafters while joists run parallel to the length of the building. The top flange of the joists fit immediately below the top flange of the mezzanine beam.

The economy of the mezzanine floor is affected by the applied load and support column spacings. Multi-level equipment platforms, catwalks, staircases etc. can be accommodated, if complete data is available.

Interarch metal buildings have the flexibility to allow integration of all kinds of standard bought out accessories. Interarch also supplies proprietary accessories.