- Pre-Engineered Metal Building Systems

- TRACDEK® Roofing & Cladding Systems

- Interarch Life - Non Industrial Buildings

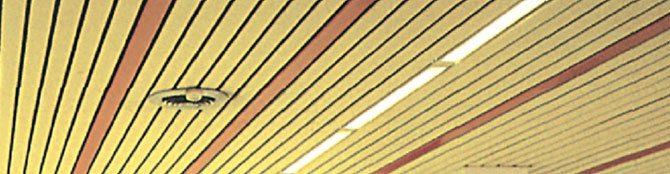

- TRAC® Suspended Ceiling Systems

- Pre-Engineered Heavy Steel Structures for Tall Buildings and Infrastructure Applications

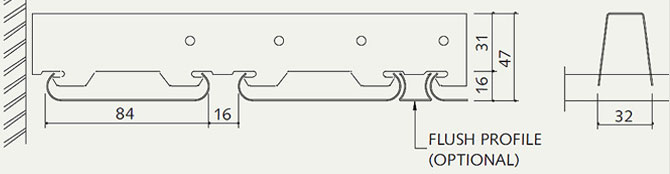

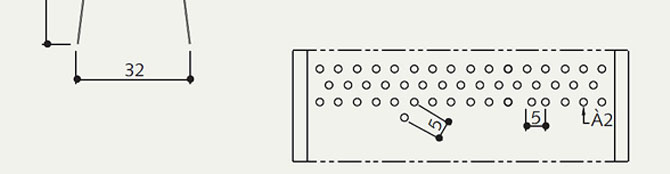

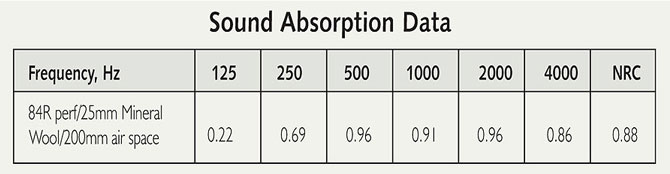

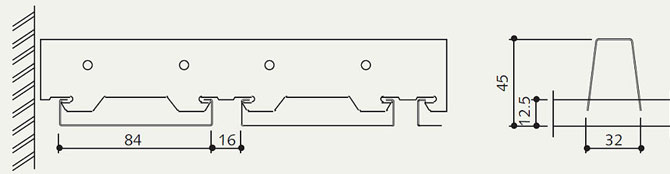

84mm wide x 16mm deep, made out of 0.50mm aluminium alloy AA3005/3105/5052 with stove enamelled coil coated finish / 0.45 galvanised steel with stove enamelled coil coated finish. (Colour according to TRAC® colour chart and availability chart). Panel length upto approx 5m. When perforated, hole diameters are 2mm on 5mm centres (standard) or 1mm on 2.5mm centres (microperforated), the holes representing15% of the perforated area.

32mm wide, 39mm deep, made out of 0.95mm aluminium alloy AA 5052/0.6mm galvanised steel, with prongs to hold the panels in a module of 90mm/100mm (gap 6/16mm, open). Optional gap closures with recessed or flush join profiles for 16mm gap.

Made of enamelled aluminium, for 100mmmodule (16mm gap). Suspension: By means of suspension rods and spring clips. One suspension for every 1.5 to 2 sq.m.

1.3m max. with insulation, 1.5m max. without insulation.

1.3m max. spacing of suspension rods

Panels will be finished on exposed side with 20 microns polyester coil coating over primer and on rear side with a wash coat.

84mm wide x 16mm deep, made out of 0.60mm aluminium alloy AA 3005 / 3105 / 5052 with stove enamelled coil coated finish. (Colour according to TRAC® colour chart and availability chart). Panel length upto approx 5m

34.5mm wide, 48mm deep, made out of 0.95mm aluminium alloy 5052, with prongs to hold the panels in a module of 90mm / 100mm (gap 6 / 16mm open). Optional gap closure with flush join profile for 16mm gap.

By means of rigid suspension rods or on steel substructure.

800mm max.

500mm max. spacing of suspension angles.

Panels will be finished on exposed side with coil coated stove enamelled PVF2 or polyurethane paint with a wash coat on the rear side.

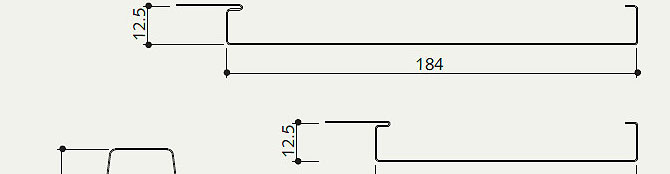

84mm/184mm wide x 12.5mm deep, with a recessed flange of 23.5mm, made out of 0.50mm aluminium alloy AA 3005/3105/5052 with stove enamelled coil coated finish 0.45mm galvanised steel with stove enamelled coil coated finish. (Colour according to TRAC® colour chart and availability chart). Panel lengths up to approx. 5m

32mm wide, 39mm deep, made out of 0.95mm aluminium alloy AA 5052/0.6mm galvanised steel, with cutouts to hold the panels in a module of 100mm (84C) or 200mm (184C), gap 16mm closed.

By means of suspension rods and spring clips. One suspension for every 1.5 to 2 sq.m.

1.3m max. with insulation, 1.6m max. without insulation.

1.3m max. spacing of suspension rods.

Panels will be finished on exposed side with 20 microns polyester coil coating over primer and on the rear side with a wash coat.

84C ceilings can also be used for exterior applications when suspended by rigid suspension rods or mounted on a steel substructure. 84C exterior ceiling is available in 0.50mm aluminium alloy AA 3005/3105/5052 with stove enamelled coil coated finish. (Colour according to TRAC® colour chart and availability chart). Panel Span: 800mm max.

500mm max. spacing of suspension angles.

Panels will be finished on exposed side with coil coated stove enamelled PVF2 or polyurethane paint with a wash coat on the rear side.

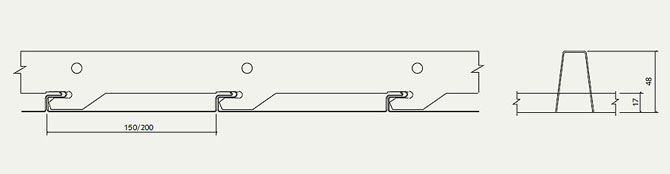

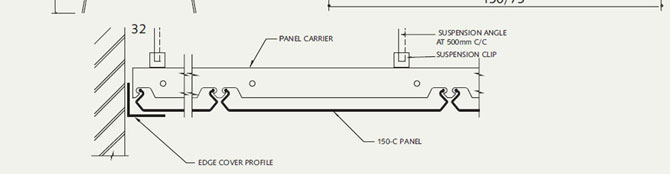

150mm wide x 17mm deep, made out of 0.60mm aluminium alloy AA 3105/3105/5052 with stove enamelled coil coated finish / 0.50mm galvanised steel with stove enamelled coil coated finish. (Colour according to TRAC® colour chart and availability chart). Panel length upto approx 5m

34.5mm wide, 48mm deep made out of 0.95mm aluminium alloy AA5052/0.60mm galvanised steel, with prongs to hold the panels in a module of 75 /150mm.

By means of suspension rods and spring clips.

1.5m max. with insulation, 1.8m max. without insulation

1.5m max. spacing of suspension rods.

Panels will be finished on exposed side with 20 microns polyester coil coating over primer and on the rear side with a wash coat.

Exterior150mm wide x 17mm deep, made out of 0.60mm aluminium alloy AA 3105 / 5050 with stove enamelled coil coated finish / 0.50mm galvanised steel with stove enamelled coil coated finish. (Colour according to Trac colour chart and availability chart). Panel length up to approx 5m.

34.5mm wide, 48mm deep made out of 0.95mm aluminium alloy AA 5052/0.60mm galvanised steel, with prongs to hold the panels in module of 150mm.

By means of rigid suspension angles or mounted on a steel sub-structure.

1000mm max.

500mm max. spacing of suspension angles.

Panels will be finished on exposed side with coil coated stove enamelled PVF2/ polyurethane/SMP paint with a wash coat on rear side.

TRAC® ceiling type 75/150C distinguishes itself from the other types because of its smooth, closed appearance. The panels about each other with a narrow V-groove. They are installed to carrier profiles and can be simply demounted individually, by inserting a plain strip between the profiles.

As with all TRAC® ceilings, the 75C/150C can be applied in all types of buildings and because of their closed appearance they are particularly suitable for domestic applications: living rooms, kitchens, corridors etc.

75mm/150mm wide x 15mm deep with bevelled groove between panels, made out of 0.50mm thick aluminium alloy AA 3005/3105/5052 or 0.5mm thick galvanised steel. (Colour according to TRAC® colour chart and availability). Panel lengths upto approx 5 m. When perforated, hole diameters are 2mm on 5mm centres (standard) or 1mm on 2.5mm centres (micro-perforated), the holes representing 15% of the perforated area (150C only).

32mm wide, 39mm deep made out of 0.95mm aluminium of 0.6mm galvanised steel, with prongs to hold panel in a module of 15mm.

By means of G.I. rod hangers and suspension clips.

1.3m max. with insulation, 1.5m max. without insulation.

1.3m max. spacing of suspension rods.

Panels will be finished on exposed side with 20 microns polyster coil coating over primer and on the rear with a wash coat.

200mm wide 45mm deep, made out of 0.70mm thick aluminum alloy AA 3105/5050 / 0.5mm thk. galvanised steel. Panels are available in standard lengths of 2 m and 3 m.

200mm wide, 40mm deep made out of 0.5mm galvanised steel with spring tee to hold the panels in module of 200mm. (Short sides of each plank are raised and pipped and stopped to ensure positive engagement into the clip-in panel carriers.)

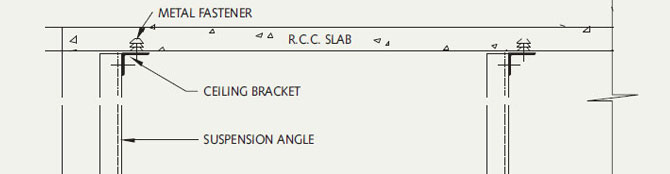

By means of rigid suspension angles or mounted on a steel sub-structure.

800mm max. for interior ceilings, 600mm max. for exterior ceilings.

Panels will be finished on exposed side with 20 microns polyster coil coating over primer and on the rear side with a wash coat.

Panels will be finished on the exposed side with 50 microns epoxy polyster powder paint.

Interior / ExteriorTRAC® tile and plank design ceiling system has been developed to meet both practical and aesthetical requirements of modern ceilings. The major advantages of the TRAC® tile/plank system are innovative suspension systems, optional rigid grid system for suspension of exterior ceilings, choice of tile material, extensive range of colours and finishes and a choice of perforations and flexibility in design specially with the plank ceiling system. The tile/plank ceiling systems are offered in stove enamelled coil coated steel and aluminium and powder coated steel and aluminium finishes and offer the advantage of easy cleaning, non-static properties and inert material.Incandescent and halogen type spot lights can be easily incorporated in the tile ceilings and fluorescent fittings within the plank ceilings.

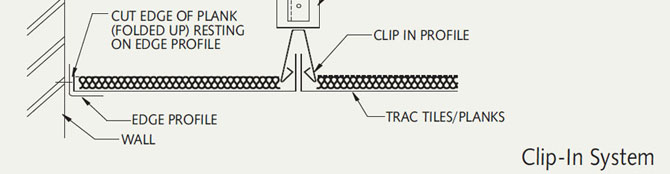

Tiles and plank ceilings are available with clip-in, lay-in and C grid suspension systems.The clip-in system consists of 0.5mm galvanised steel clip in profile which is used as the primary suspension and if required, as a secondary suspension.

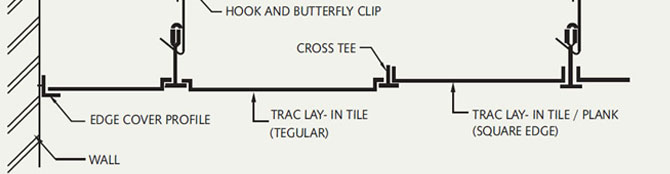

The lay-in system comprises the Trac 8011 exposed grid suspension. This grid features stab-in coupling and is demountable.

The C-grid suspension system consists of exposed C-shaped runners which are installed parallel to each other or in a square grid to form continuous main courses. The planks are hooked onto these grids.

Tiles are manufactured out of coil coated galvanised steel/aluminium alloy AA 3105/3005/5202 on advanced equipment, which includes several levelling stages in the manufacturing process. For the clip-in tile, two sides of each tile are raised and pipped and stopped to ensure positive engagement into the spring tee yet allow demounting of individual tiles.

For the lay-in system, the tiles have a flange on each end which lays on the exposed grid. All tiles have square/bevelled edges.

Planks are manufactured out of coil coated aluminium alloy AA 3105/3005/5202 galvanised steel produced on advanced equipment which includes several levelling stages.

Tiles/planks are trimmed along the wall perimeter by means of 19x19mm roll formed steel or aluminium edge cover profile.

Steel tiles/planks: Steel tiles/planks are finished on exposed side with 20 micron polyester coil coating over primer in approved shade and backing coat on rear surface (nominal 5 microns), or with a 50 micron epoxy polyester powder coating on exposed surface.

Aluminium tiles/planks: Aluminium tiles/planks are finished on exposed side with 20 micron polyester coil coating over primer in approved shade and backing coat on rear surface (nominal 5 microns), or with a 50 micron epoxy polyester powder coating on exposed surface. Wall angles are finished with 50 micron epoxy polyester powder coating paint in broken white shade.

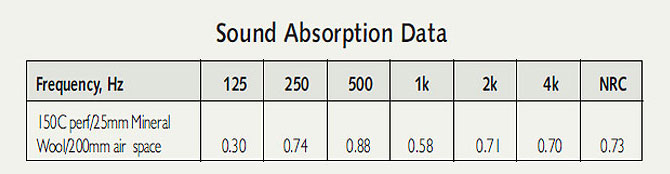

TRAC® tiles and planks are also available with perforations for providing acoustic performance characteristics. TRAC® tiles and planks are perforated as a standard with 2.5mm dia. holes at 5.5mm centre to centre in a regular pattern. Other special/non-standard perforations are also available. Tiles and planks when backed with 25mm thick resin bonded mineral wool (48 kg/m2) provide good sound absorption. Tiles and planks are also available with a factory applied acoustic tissue to the back side, which provides good sound absorption.

The TRAC® GRG range of ceiling tiles are manufactured from glass reinforced gypsum and comprise non-combustible gypsum casting plaster reinforced with a glass fibre membrane resulting in a light weight, strong and prestressed panel.

The plaster has a silky smooth or textured moulded finish.

The tiles are normally supplied in their natural white finish and can be pre-decorated to order.

All designer tiles are designed for installation on a standard 600x600mm module 24mm table exposed metal grid and are precision made to within plus or minus 0.25mm.

For a guide, the tile weights are shown below but may vary depending upon the gypsum source.

| Tile | Kg / tile | Kg / m2 | |

|---|---|---|---|

| T206 | Fine Texture Tiles | 3.8 | 10.8 |

| T506 | Travertine Texture Tiles | 3.9 | 10.8 |

| T826 | Shallow Coffers | 4.5 | 12.5 |

| T906 | Open Cell Tiles | 4.1 | 11.4 |

| T906C | Closed Cell Tiles | 5.6 | 14.5 |

Non-combustibility: TRAC® GRG tiles are rated non-combustible as defined in BS 476: Part-4, 1970.

Surface Spread of Flame: TRAC® GRG tiles are rated Class 1 for surface spread of flame to BS 476: Part-7, 1987.

Fire Propagation: Test results to BS 476: Par-6, 1989 indicate a Class O surface.

Smoke and Toxic Fume Emission: The tiles are zero rated for smoke emission. No toxic fumes are given off.

The tiles have excellent moisture resistance and can be used in areas of high humidity including covered external areas, kitchens and bathrooms. Tested in an atmosphere of 95% R.H. at 12°C for 14 days, the tiles did not sag or distort and showed only a minimal increase in weight. Unlike most other ceiling materials, this important attribute can often be used to speed up the building program by installing the ceiling before the building is fully weathertight.

TRAC® GRG tiles will not support the growth of bacteria or other micro-organisms.

Under normal conditions TRAC® GRG tiles will not deteriorate and can be expected to last the lifetime of the building.

Suspension system is standard 24mm table exposed metal grid. TRAC® exposed metal grid systems are designed for maximum strength. The grid features main runners and cross tees roll formed from galvanised steel. The main and cross runners are provided with stab-in coupling for quick installation. The runners are pre coated to construct a variety of lay outs. Main and cross runners are provided with a coil coated steel capping on the exposed table in off-white colour. Grid system features main and cross tees 38mm high. The grid is suspended from the roof with GI wire rods and or quick adjustment suspension hangers at maximum 1200mm along the main runners. TRAC® GRG tiles are designed for lay-in mounting from below into standard grid.

TRAC® GRG tiles are supplied and packed in cardboard cartons. Cartons should be transported and stacked in the vertical position only, never flat; the stack should be a maximum of three cartons high. Similarly, tiles should be stacked vertically when awaiting fixing.

Main tees should normally be fixed at 1200mm centres with hangers every 1200 mm along the length of the tee. The tees would be in filled with 1200mm and 600mm cross tees. The grid manufacturers recommendations should be followed at all times.

Note: All perimeter tiles may be supported on only 3 sides without risk of sagging. Tiles can easily be cut by using a carpenters fine tooth saw; the lines should be placed face down on a flat, clean surface for cutting.

The Interarch Architectural Projects and Service Group (ASG) provides customers with complete design, engineering, and drafting support. ASG can help you convert your most imaginative designs into reality.

Shop drawings and detailed bill of quantities are prepared for all projects to ensure correct product supply and application.