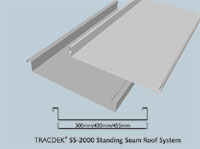

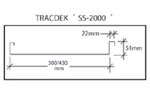

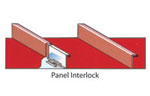

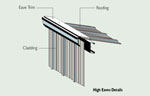

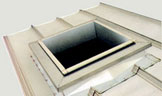

TRACDEK® Hi-Rib®, a pierced fixed roof and wall covering system, consists of structurally-engineered profiled panels that are available in single length (up to 12 metres) and are fixed by means of self-drilling fasteners. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing.

he patented fluted side lap makes TRACDEK®Hi-Rib® completely watertight.

The side lap is totally weatherproof. Any moisture drawn in by capillary action is trapped and dispersed by normal run-off.

Long lengths and weatherproof side lap allow TRACDEK®Hi-Rib® to be used safely on roof pitches as low as 3 degree (approximately 1 in 20) in single-sheet lengths, 5 degree (approximately 1 in 11) with end laps, and for vertical cladding.

Mass Hi-Rib® 100 - Standard Execution

| |

Total Coated Thickness (mm) |

Approx. mass per unit area kg/ m2 |

Approx. covrage per unit area m2/ ton |

| Bare Gavalume® high tensile steel |

0.50 |

4.12 |

242 |

| Gavalume® high tensile steel, colour coate |

0.50 |

4.24 |

235 |

| Galvanised steel, colour coated |

0.50 |

4.25 |

235 |

| Galvanised steel, colour coated |

0.50 |

4.56 |

219 |

| Galvanised steel, colour coated |

0.55 |

5.03 |

198 |

| Galvanised steel, colour coated |

0.65 |

5.97 |

167 |

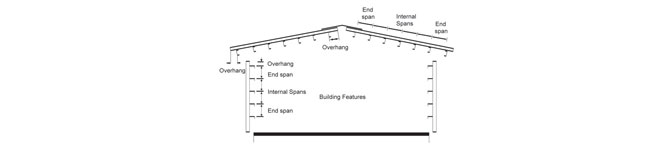

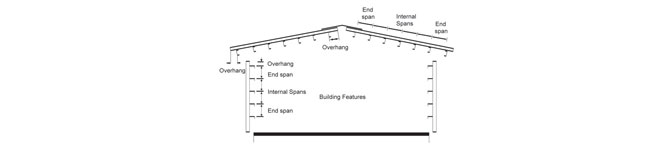

Support Spacings

| Type of Span |

0.50 mm TCT

steel (550 Mpa) |

0.50 mm TCT

steel (240 Mpa) |

| Roofs |

| Single |

900 mm |

800 mm |

| internal span |

18000 mm |

1400 mm |

| End span |

1200 mm |

1000 mm |

|

Overhangs |

| Without edges stiffening |

150 mm |

150 mm |

With edges stiffening

|

300 mm |

300 mm |

| Walls |

| Single span |

1500 mm |

1100 mm |

| internal span |

2000 mm |

1400 mm |

| End span |

1800 mm |

1200 mm |

| Overhangs |

300 mm |

300 mm |

Notes to Table

- Support spacings listed have been determined on the basis of suitability of cladding to carry installation and /or maintenance roof traffic and wind loads.

-

Wind loads are determined in accordance with IS 875 (part 3) –

1987 for a regional basic wind velocity of 47 m/s, for buildings

up to 10 m high in terrain category 3, and assuming an internal

pressure coefficient of +0.2. This condition would apply to

average suburban or industrial areas for buildings which do not

have large fixed openings.

- Support spacings for buildings with more severe wind loading

conditions than those listed in note 2 may be determined in

accordance with IS:875 (part 3) – 1987 using table 2 below.

- Support spacings for roofs are generally governed by foot

traffic for low pitch roofs (point load requirement of IS: 875

(part 2) – 1987), and by wind loading for high pitch roofs.

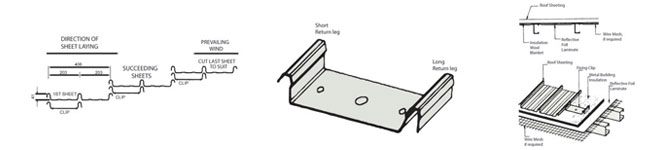

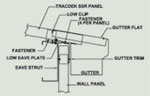

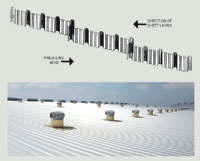

Sheet Laying & Fixing

Roofing

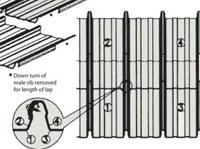

Sheets are lifted onto roof supports with ribs up and with overlapping ribs (female) facing towards the starting edge. To commence fixing, the first sheet is placed in position with the female rib, in line with other building elements, and fastened as recommended. The female rib (with turned-down free edge) of the second sheet is lapped over the male rib (with turned-out bottom edge) of the first sheet and the recommended side lap fasteners are inserted to hold the lap firmly in place before fastening the second sheet to supports. The second sheet procedure is followed for all subsequent sheets.

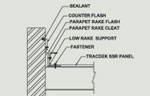

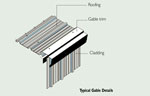

Walling

For walling applications, the procedure outlined for roofing is followed. The recommended minimum end lap for vertical wall cladding is 100 mm. When the roof pitch is less than 15 degree, or where the roof is exposed to extreme weather conditions, the tray between the ribs is turned up approximately 80 degree at the high end of the roof sheeting and turned down slightly at the low end. A Turn-up tool is available for this operation which can be carried out before or after sheets are fixed in position. If turned up after fixing, at least 25 mm clearance is required at the end of the sheet to position the tool.

Minimum end lap is 150 mm, and for roof pitches below 7 degree, the lap is sealed with a recommended sealant. The maximum roof run from top to bottom does not exceed 27,500 mm for a single run of sheeting. Expansion joints are required in sheeting for longer roof runs.

Location of Fasteners

At Supports

TRACDEK® Hi-Rib® roofing is fastened by conventional crest fixing to timber and steel supports; in each case there should be four fixings per sheet at all supports. Wall claddings are fixed by crest or valley fixing.

It is important for all fasteners located in pan to be as close as possible to ribs as shown.

Side Lap Fasteners

Lap fasteners are essential to hold the side laps of sheets firmly in place and maintain a weather-proof joint. Side lap fasteners are required at midspans for purlin spacing over 900 mm and also for girt spacing over 1200 mm. In the applications where valley fixing is used, a side lap fastener is also required alongside each valley fastener, or a crest fastener is used at the side lap.

Recommended Fasteners

TRACDEK® Hi-Rib® should be fixed with the following hexagonal washer head with seal fasteners which are available from Interarch in corrosion protected zinc coated finishes with colour heads or in stainless steel.

Fixing through Crest to Hardwood Support: Type 17 No. 12-11 x 65 mm (self drilling)

Fixing through Pans to Handwood Supports (For walls only): Type 17 No. 10-12 x 25 mm (self drilling)

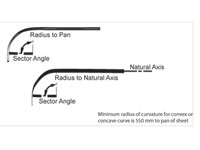

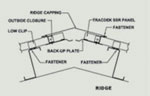

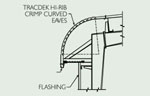

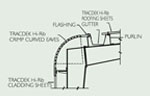

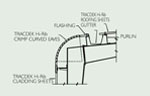

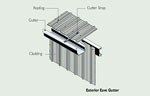

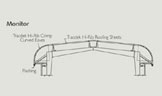

Crimp Curved Roofing and Cladding

Crimp Curved TRACDEK® Hi-Rib® is developed to provide versatility and creativity. It brings new and refreshing design to commercial, industrial and domestic buildings.

The combination of curves and contours in concave and convex shapes with flats and angles in TRACDEK® Hi-Rib® produce many aesthetically pleasing buildings.

This design freedom can result in significant cost saving in construction mainly due to:

- Less supporting framework required for parapets and roofs.

- Reduction or elimination of many flashing/cappings.

- Less cladding material required for covering a given curve

Crimp Curved TRACDEK® Hi-Rib® is available in polyester coated galvanized steel or organic coated Galvalume®.

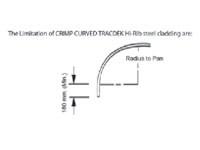

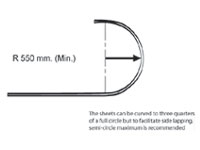

For Crimp Curved TRACDEK® Hi-Rib®, the minimum radius of curvature for either concave or convex curving is 550 mm to inside of sheet.

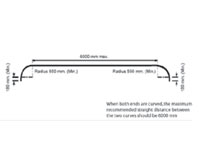

Minimum length of sheet at either end of a curve is 180 mm at leading end and 200 mm at the lagging end

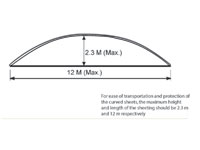

The sheets can be curved to 3 quarters of a full circle (for convex and concave) but to facilitate side lappings, semi circle maximum is recommended.

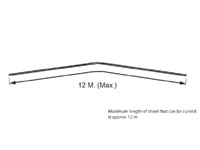

Maximum length of straight sheet that can be curved at its height (for Ridge Application) is approximately 12 metres.

Application

TRACDEK® Hi-Rib® roof and wall systems are ideally suited for regions which receive heavy rainfall and can be used on slopes as low as 1 in 20.

TRACDEK® Hi-Rib panels can be used as internal liners for double-skin roof and wall construction, with or without insulation. TRACDEK® Hi-Rib curved panels are also offered for special architectural requirements.